- Lithium is a mineral that is used in batteries, from those for electric vehicles to those for computers and phones.

- Demand continues to increase – with an expected 30x jump required in the next few years – but the extraction process is currently time and energy intensive, leaving the industry poised for a shortage by 2023.

- Lilac Solutions, which aims to “scale lithium supply for the electric era”, has an innovative solution that extracts the mineral from brine, faster and with far fewer resources.

A shift in global consumption over the last few decades has meant a shift in the global supply chain. And as the calls for electric vehicles get stronger, the demand for lithium is growing as well. Lithium is the mineral that’s used in car batteries, as well as many electronics like computers and smartphones. Demand for lithium has been increasing amid a dwindling supply, with a lithium shortage expected by 2023.

Lilac Solutions is trying to fix that. They’ve been attracting investment from large companies like BMW to develop their new lithium production technology. They claim that with their development methods they can produce in two hours what would normally take two years to procure, using only a fraction of the land that the traditional process would use.

This is fantastic news for both the electronic vehicle industry as well as the environment. Being able to use ten acres instead of 10,000 to produce the same amount of raw material is an astonishing feat that would save an abundance of land, natural habitats, and wildlife.

Lithium is traditionally sourced in one of two ways: hard rock extraction or saltwater deposits. Mining lithium from hard rock requires a lot of energy and is expensive. Extracting the metal from saltwater deposits, also called brine, is more economical but requires quite a bit of water.

The majority of the world’s lithium reserves are found in brines. The conventional process uses evaporation ponds that require a lot of land and time to extract the lithium that can be further refined for use in electronics. The evaporation method is also largely dependent on the weather. The result of the process yields a relatively small amount of lithium compared to what Lilac Solutions is able to do with their new technology.

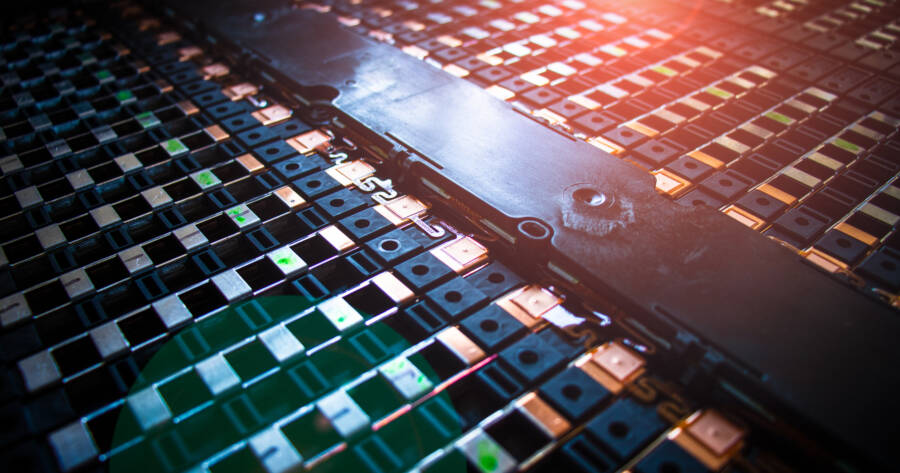

Lilac has found a way to extract lithium from brines without the need for evaporation ponds. Lilac uses ion exchange beads that filter and capture the lithium from these ponds, doing minimal harm to the environment. This ion exchange technology has been used in a variety of water treatment applications but has never before been used to extract lithium.

The brine is passed through a truck full of ion exchange beads that captures the lithium and rejects the other impurities in the water. When the beads are full of lithium, they are washed with hydrochloric acid, producing lithium chloride. The lithium chloride is then processed on-site using conventional equipment to create the finished product that is then sold to battery makers.

With the growing demand for lithium outstretching our current supply, technology and innovation are needed to create more efficient and sustainable extraction methods. Lilac Solutions is offering an answer to the lithium problem with a goal of having this technology implemented on a large-scale by 2024. With that being about the same time as the predicted global lithium shortage, Lilac Solutions are poised to be the answer to this problem.